High quality production saves you cost.

Quality isn’t just a process, it’s designed into the process. Our results speak for themselves. When it comes to conformance, our team is devoted to your exact specification and will not deter from your functional and design needs.

Consolidate your manufacturing.

We connect you to all manufacturing capabilities through a single touch point. This reduces your time spent managing vendors. Our consolidation programs combined with our ultra-low NCMR rates create low-risk optimization of your go to market process.

Metrology for exact conformance.

Quality isn’t just a process, it’s designed into the process. Our results speak for themselves. When it comes to conformance, our team is devoted to your exact specification and will not deter from your functional and design needs.

Experience translates into trust.

Through years of hands on experience in the quality engineering and manufacturing industries, we have established a high level of trust with our customers. We are driven by the exceptional short term and long term results we provide to our customers.

Industry

Process

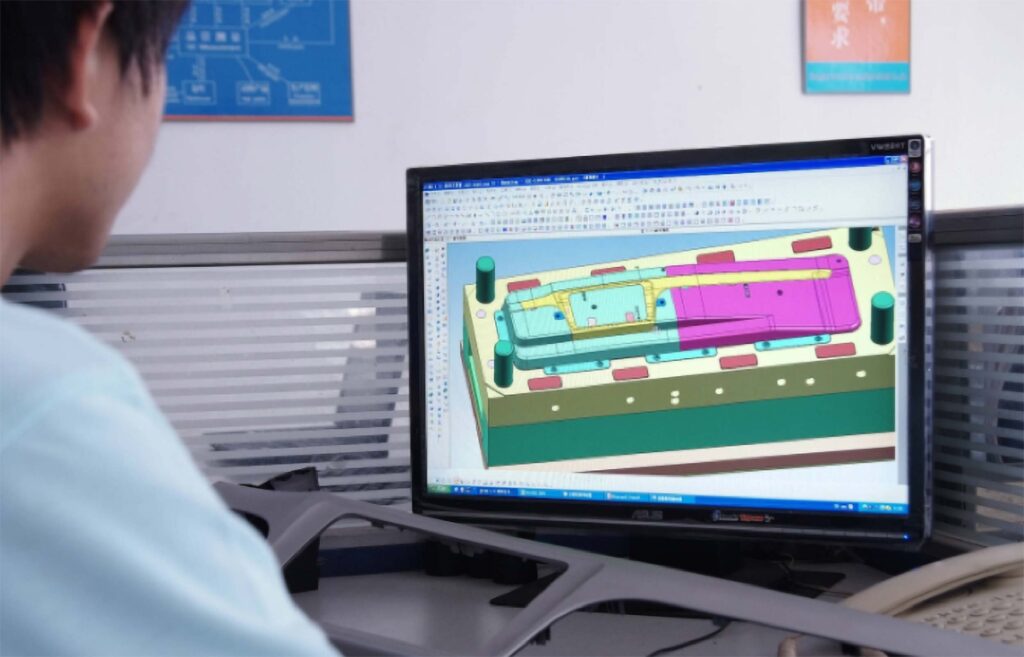

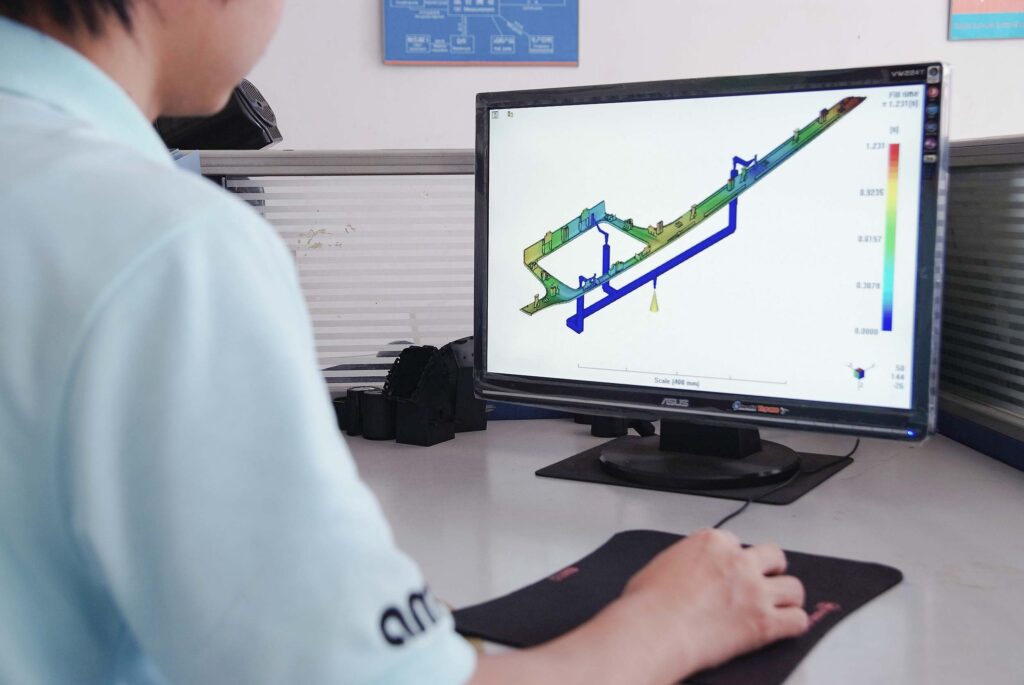

Injection Molding

Injection molding is an excellent manufacturing method for large scale production. It is most often used in processes of thousands or even millions of units with highly accurate and repeatable results. Thermoplastic resin is heated and injected into the preformed mold, cooled and ejected resulting in the desired design.

Compression Molding

Compression molding is accomplished by utilizing pressure and heat to form thermoplastic or other materials in a mold. Tooling costs are generally lower than injection molding, but the process can be slower, a factor to be considered for large volume production runs.

Roto Molding

The extrusion process involves compressing a blank of raw material through a die to achieve the desired cross-sectional profile. The advantage of this process is the ability to make highly complex shapes and to form lengths that can be continuous.

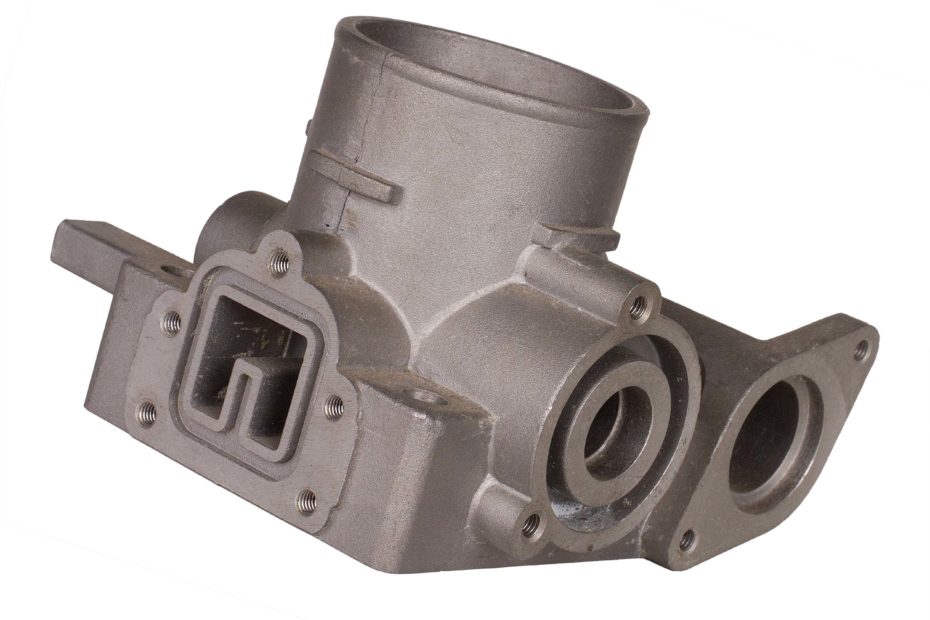

Die Casting

Die casting is similar to injection molding, however die casting separates itself by the use of metal materials. Hot molten metal is forced into a mold cavity made of two hardened steel dies. This process is ideally suited for high-volume production due to the higher tooling cost of the casting molds.

Metal Stamping

Metal stamping involves placing a “blank”, flat sheet metal or even polystyrene into a press containing a die to form the metal into the desired shape.

Extrusions

The extrusion process involves compressing a blank of raw material through a die to achieve the desired cross-sectional profile. The advantage of this process is the ability to make highly complex shapes and to form lengths that can be continuous.

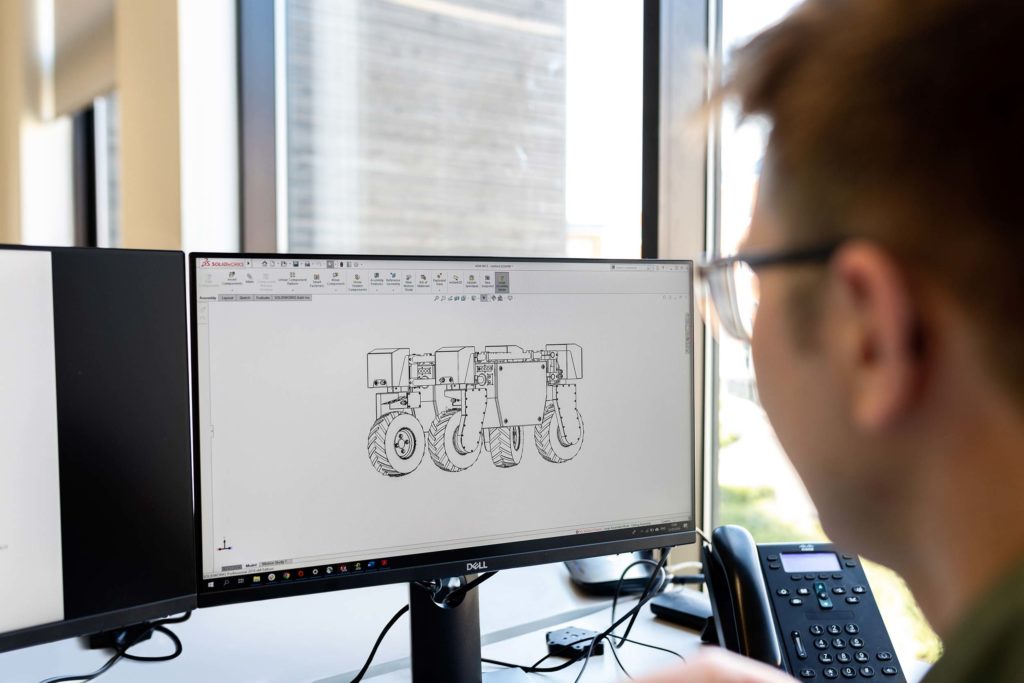

Welding & Machining

Machining is the process by which raw material is cut into a final shape. This is typically done by a CNC machine. Often, these processes are used in the creation of machine tools such as molds used in other manufacturing processes.

Powder Coating

Powder coating finishes are a highly durable and effective option for many companies and product types around the world. The process involves applying dry powder through electrostatics to the product surface, followed by a curing process typically with heat.

Why outsource your manufacturing?

There are quite a few benefits to outsourcing your manufacturing process. With the right partner, these include lower start-up costs and higher potential quality.

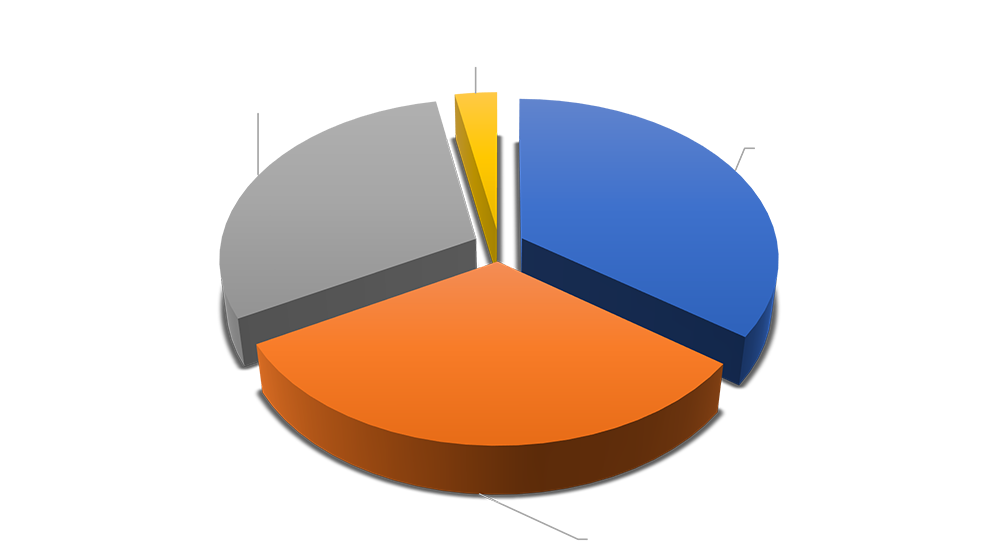

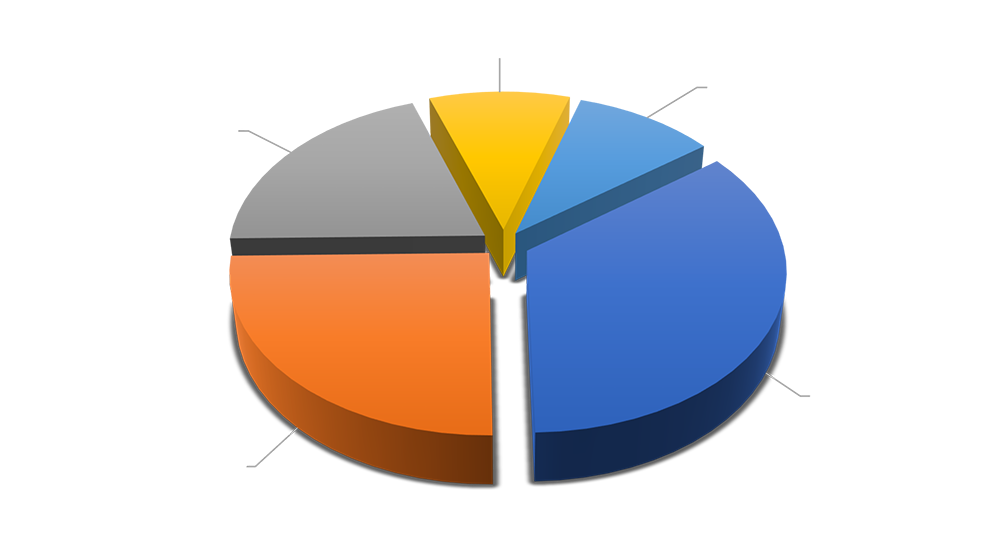

US Manufacturing

Asia Manufacturing

We manufacture your products with quality, integrity, and responsiveness.

Free Resource

What is poor quality actually costing you?

Poor quality costs a lot, but do you know the full extent to those costs? In this free resource we detail ways in which the hidden costs of quality can permeate and hamstring companies.

Why Quality Control Does Not Necessarily Improve Quality

July 3, 2020

Quality is a hot-button issue in manufacturing. That’s because many companies understand that poor quality carries with it great cost. However, even though this understanding generally exists, most companies are unaware of the true cost of poor quality.

Non-Conformance in Manufacturing and How to Stop It

Sept 9, 2022

Non-conformance in manufacturing processes can cause issues including increased costs. But what is nonconformance and how do you correct it?

How DFM Can Dramatically Cut Product Costs and Increase Quality

June 18, 2020

The engineering work of DFM or Design for Manufacturing is the practice of designing a product so that is able to be efficiently manufactured. It is set apart from traditional functional engineering which seeks to achieve a desired mechanical or visual design.